Dual-Screen™ Shale Shaker Screen Technology

The only one of its kind.

The Problem with Conventional Screens

The problem associated with the use of conventional single deck screens used on shale shakers is associated with optimizing the removal of the cuttings; the more cutting removed the better which entails the selection of finer mesh screens, and the loss of drilling fluid which is exponentially proportional to the surface area of the cuttings removed.

-

Smaller cuttings have significantly more surface area then large cuttings; for a given weight of cuttings, and thus convey more drilling fluid out of the system then the larger cuttings

The effect for the driller is essentially a uncompromising one, if he selects coarser screens his fluid systems properties deteriorate and the drilling process is impeded and can be catastrophically affected, if the driller selects finer screens the fluid properties are maintained but the losses of drilling fluid increase due to replacement costs and disposal fees.

Additional Effect of Conventional Shaker Screens: Causes large and small cuttings to be separated at the same time. Creating the following Problems.

- Increased amount of cuttings means more material is present on the screen to cover the screen openings which reduces the opportunity for fluid to pass through the screens

- The mass of the large cuttings causes them to react more violently to the vibration of the shaker which means they transit the screen deck more rapidly than the smaller cuttings meaning they pass over the smaller cuttings during the transition process. This causes the smaller cuttings to be “hammered” by the larger cuttings and a significant proportion of them are pounded through the screen material as a result. This effect defeats the purpose of the selection of finer screens

- Another solution employed by shaker designers for reducing fluid loss during the process is to build in a tilt against the flow on the shaker deck; MI Swaco uses 2° and NOV Brandt 5° this can be augmented by the driller by several degrees as well, which increases transition time for cuttings. This effect causes the cuttings to remain on the vibratory deck longer. By doing this the driller causes the cuttings to be impacted thousands of times more than normal with forces of 6-9 times its weight. The effect of this longer transition is further deterioration of the cuttings and the increase passage of these deteriorated materials through the screens.

The Dual-Screen™ Solution

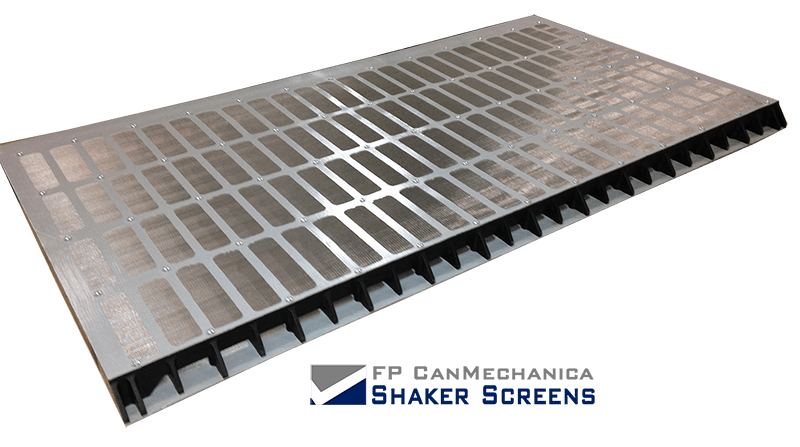

The intent and purposes the Dual-Screen™ or Double cut screen is a simple improvement over the conventional screen. It has a different composite/plastic core that allows for the mounting of an upper screen and a lower screen and provides for a channel in the center which allows the fluids and cuttings to be processed on two levels concurrently.

This technology stacks one coarse separating screen above a lower finer screen which causes the coarse cuttings to be separated onto an upper screen level from the finer cuttings which are relegated to a lower screen level. By doing this the coarser solids; which are conveyed more rapidly by the vibrations of the shaker off of the shaker, do not interact with the slower moving finer solids which are on the lower screen. The result is a more effective removal of both fine and coarse material, reduced interaction of cuttings and a complete lack of requirement for the tilting of the shaker against the flow of the cuttings. Another advantage of this approach is the separation of the cuttings in this manner allows for less solids on each screen which means more open area for the fluid to pass through which reduces fluid losses as well.

The Proof

The technology developed by FP CanMechanica™ has been evaluated in field trials and test labs in the US and Canada and the results are more than encouraging. Trials show that shaker flow handling capacity can increase up to 210% and that it was impossible in testing to “sand off” the screens (Sand off is a procedure for trying to plug all the screen openings by pouring a sand of multiple sizes onto the screen in an attempt to plug all the openings)

Further, testing in the field with Talisman Energy (Now Repsol) and confirmed by independent labs has shown that the level of fluid losses using the Double-Screens™ is lower than levels achieved with the most advanced vacuum supplemented Shakers which incur daily additional costs of $600-$1000. These screens potentially pay for themselves in as little as 2-3 operating days.

Field Test: NOV/Brandt King Cobra Shaker

The video to the right shows a side by side comparison between, Convention metal single screens (NOV/Brandt Screens) On the Right, and Dual-Screen™ on the left.

- 85% of Fluid is being directed over the Dual-Screen™ on the left.

- Screen are 80 API Top, 170 API Lower

- 15% of the Fluid is on the conventional shaker screens on the right

- 170 API Screen

- Pooling of fluid is evident

Dual-Screen ™ Benefit

- Dual-Screen ™ Doubles the processing area of the shaker deck

- Field trials indicate that Dual-Screen ™ equipped shakers processing rates can double

- Mongoose field trial had a single shaker with 200 mesh final cut processing efficiently at 2 cubic metres per minute.

- Initial trials show a dramatic increase in “First Cut” efficiency of shale shakers. Minimum increase in screen cut of 150 API mesh. Yielding improved drilled solids management in both weighted and unweighted fluids. Which provides:

- Reduced drilling fluid makeup requirements, volume building, and maintenance costs.

- Better control over fluid density and viscosity. Lowers pump energy requirements and reduces fuel / energy consumption.

- Faster drilling rates

- Reduced drilling fluid waste disposal costs, labour, fuel, sawdust, trucking, tip fees etc.

- Reduces or eliminates the need for centrifuges and centrifuging lowering energy consumption, labour and rental costs.

- Eliminates the need for secondary fluid processing equipment, Vac-Screens, Drying Shakers etc.

- Increased operation life

- Dual-Screen ™ can be fabricated for virtually all shakers that use prestressed screens

- Dual-Screen ™ can be used on Drying Shakers

- Dual-Screen ™ can be used on Bead Recovery units

Dual-Screen ™ accomplish every goal that can be achieved by fine shaker screen operation.

Dual-Screen ™ Features

- Patent Pending Composite Frame Design

- Weight equivalent or lower then MI single deck urethane screen

- Dual deck offers reduced losses of drilling fluid equivalent or superior to vacuum enhanced shakers

- Dual and Single Screen has superior rigidity and more even g-force distribution then conventional screens. This reduces screen wire flex in the center of the deck enhancing product life. Lowest level of by pass of any screen available.

- Significant reduction in oil based fluid losses.

- The pre-screening of coarse material on the dual also allows for the use of less open area screens on the lower level which means heavier wire can be used to enhance fine cut screen life.

- Increased usable area Vs. Traditional Screens

- Substantially longer operational life

Manufacturing Process

FP CanMechanica™ has spared no expense when it came time to manufacture our screens. The video to the right shows our manufacturing processes for our chassis.